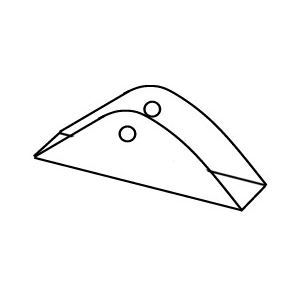

Let's just say a coil cracks where the rod gets connected to it. Not completely broken off, just cracked. I guess we could call the part, "ears". What would be the best way to fix it? If it's possible.

Super Glue?

JB-Weld?

Other epoxies?

What about if the coil has a cover, the kind that you can't see the epoxy that is used to seal the actual coil, and it has a crack in the middle, like if someone stepped on it? How would this one be fixed?

Going back to the "ears", the coils I have seen, have the "ears" attached to a small square. The square is part of the coil. That square is lifted in a crack. That is the type of crack I am talking about.

Thanks for any replies.

Super Glue?

JB-Weld?

Other epoxies?

What about if the coil has a cover, the kind that you can't see the epoxy that is used to seal the actual coil, and it has a crack in the middle, like if someone stepped on it? How would this one be fixed?

Going back to the "ears", the coils I have seen, have the "ears" attached to a small square. The square is part of the coil. That square is lifted in a crack. That is the type of crack I am talking about.

Thanks for any replies.

Comment