Announcement

Collapse

No announcement yet.

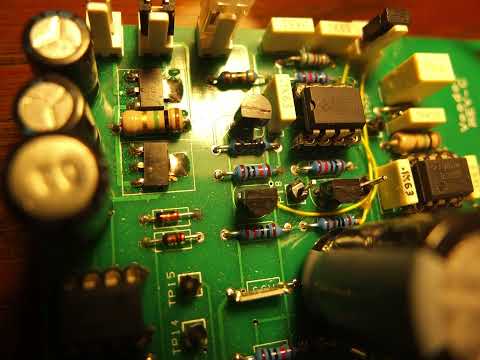

bad pi curve

Collapse

X

-

Comment

-

At the bottom of the reply box, under all the smilies, there is a button labelled Upload Attachments.

Did you test the design as you went along, or simply populate the whole board?

I'm surprised that you never noticed this problem after fitting and testing the preamp stage.

Are your power supplies stable?

Comment

-

R6 looks a little suspect, try replacing it with a short. A bad solder joint isn't always easy to see, try re-soldering joints especially right around the coil & TX. Try hard-soldering a coil to the TX pads, anything from 250uH to 1mH.

Comment

-

I first measured the value of the trimmer when the curve is critical damped. I was very confused that the value was 2 ohm. when I changed to test, the to 2 ohm adjusted trimmer with a normal 2 ohm resistor the curve was completely different. then i used a normal 500 ohm damping resistor an i had a great curve. I the original trimmer I cant find, but they were similar to this trimmer https://www.amazon.de/GTIWUNG-Potent...9&sr=8-10&th=1

What is the problem with this trimmer. I use this trimmer in other places in my voodoo detector to. will that make problems

LG Levin

Comment

. the problem was the multi turn trimmer as dampging resistor in a few hours i give more deteils

. the problem was the multi turn trimmer as dampging resistor in a few hours i give more deteils

Comment