Hi,

First of all I want to give congratulations to the all members for the excellent work developed here.

What led me to try to find information about a homemade metal detector, was the Portuguese legislation, because it does not allow detection on the beaches.

Do not wanna lose my GoldmaxxPower V4 or my Minelab Explorer SE, to the cops and still carry a heavy fine.

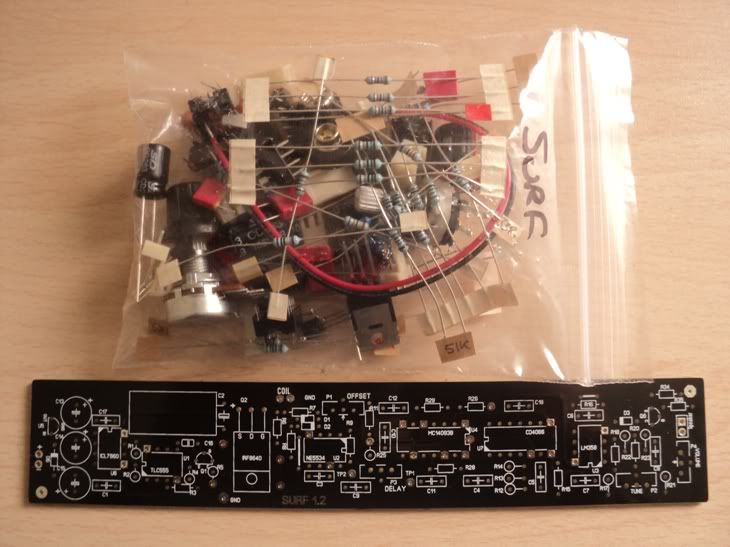

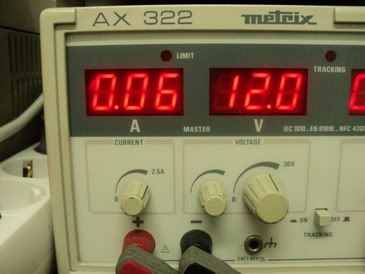

IGSL I think is a little advanced for me to start building, so I had thought about the Surf PI. I have all the equipment needed for construction.

I would like to make this topic a well detailed step-by-step, to help my detecting Portuguese colleagues and of course all those who have little knowledge and want to follow your design.

Expect lots of questions, even using the oscilloscope that is new here at home (never used one).

The next step will be to purchase a longboard from Silverdog's shop.

Best regards

Nezocas

First of all I want to give congratulations to the all members for the excellent work developed here.

What led me to try to find information about a homemade metal detector, was the Portuguese legislation, because it does not allow detection on the beaches.

Do not wanna lose my GoldmaxxPower V4 or my Minelab Explorer SE, to the cops and still carry a heavy fine.

IGSL I think is a little advanced for me to start building, so I had thought about the Surf PI. I have all the equipment needed for construction.

I would like to make this topic a well detailed step-by-step, to help my detecting Portuguese colleagues and of course all those who have little knowledge and want to follow your design.

Expect lots of questions, even using the oscilloscope that is new here at home (never used one).

The next step will be to purchase a longboard from Silverdog's shop.

Best regards

Nezocas

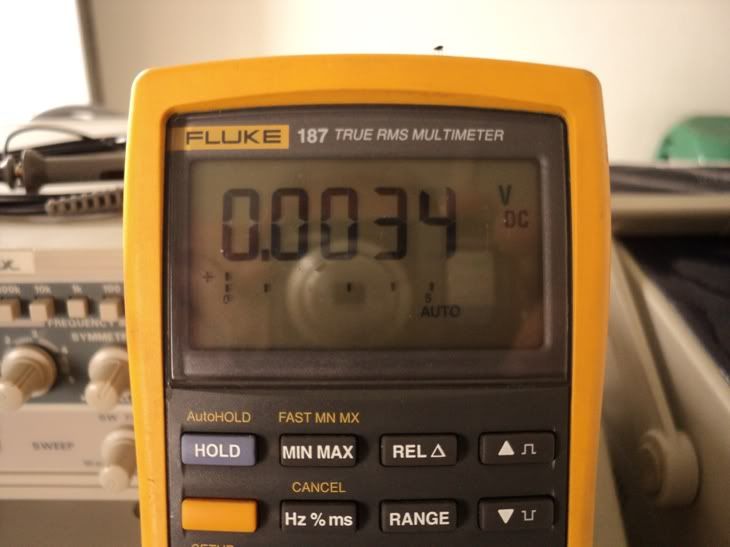

now I have zero Vdc under pin 6 of the 5534

now I have zero Vdc under pin 6 of the 5534

.

.

Comment